Support »

Custom Laser Cutting Guide

View document on multiple pages.

- 1. Capabilities

- 2. How to order

- 3. Pricing

- 4. Limitations and issues to consider

- 5. File setup instructions

- 6. Materials

1. Capabilities

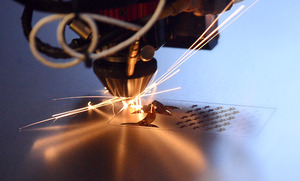

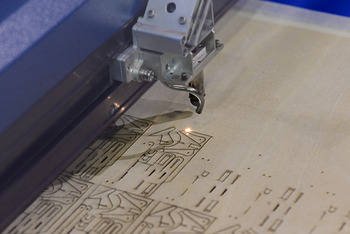

With our custom laser cutting service, you can create custom parts for a variety of projects. We can cut, score, engrave, and print almost anything you can draw, including sharp angles, smooth curves, small holes, and complex shapes.

We can…

|

Custom laser cutting of thin plywood. |

|---|

- Handle all scales of orders, from a single piece to thousands of parts.

- Provide competitive pricing and flexible turnarounds for larger orders.

- Offer expedited turnaround times up to same-day service for typical orders.

- Ship worldwide or let you know when your order is ready for pickup.

- Cut, score, and engrave layouts up to 47.5″ x 47.5″ on materials up to 48″ x 48″.

- Comfortably cut acrylic and wood up to 1/2″ thick, and up to 1″ thick under special circumstances.

- Print on plastic and wood parts with full-color, white, and varnish ink (max printing layout is 18.6″ x 12.9″).

- Cut steel up to 0.060".

- Cut very thin materials, including films and papers.

- Special-order materials that we do not stock, or cut materials that you send us.

- Cut holes as small as the laser beam width (~0.01″).

- Use a variety of vector or CAD file types, including CDR, AI, EPS, DXF, DWG, PDF, and more (see Section 5).

- Create vector drawings for you based on a sketch.

|

|

2. How to order

Having your designs made with our custom laser cutting service is quick and easy!

|

|

|

3. Pricing

The cost of a custom laser cutting job is determined by the amount of machine time, labor, and the complexity of your parts.

Here are some factors that affect the price of laser-cut parts:

- Laser-cutting and engraving cost: We price designs based on the material type, material thickness, and the complexity of your design: the more cutting, scoring, and engraving required, the more expensive your design will be, and thicker materials cost more than thinner ones. Cutting and scoring costs are based on the linear cutting/scoring distances, while engraving cost is based on the perimeter of the engravings.

- Cutting 3mm acrylic starts at $0.15 per linear inch.

- Other 3mm plastics (ABS, Delrin, styrene, PETG) start at $0.25 per linear inch.

- Scoring starts at $0.10 per linear inch.

- Engraving starts at $1 per square inch.

- Material cost: We stock various materials, which we sell by the square foot. We can also special-order materials or cut customer-supplied materials. Here are starting prices for the materials we cut most often:

- 1/8″ MDF starts at $2/sq. ft.

- 3mm birch plywood starts at $3/sq. ft.

- 3mm ABS starts at $4/sq. ft.

- 3mm acrylic starts at $5/sq. ft.

- 6mm acrylic starts at $10/sq. ft.

- Shipping cost: Quotes are sent without including shipping cost. Shipping will be added during the checkout process and we offer various USPS and FedEx options. We can also ship on your FedEx account.

- Minimum order: There is a $25 minimum for the first material and a $15 minimum for additional materials.

- Expediting cost (optional): In addition to the base quote, we typically offer expediting options for each quote, with faster service costing 20-50% more per expedited day.

- Volume pricing: Our rates decrease as the job size increases, and we can offer competitive pricing for large orders (especially if you need many copies of the same design, or if the designs are simple and do not require special handling).

- File creation: If you are unable to provide a vector or CAD file, we might be able to create the file for you. Our file creation service costs $60 per hour, with a $15 minimum.

4. Limitations and issues to consider

|

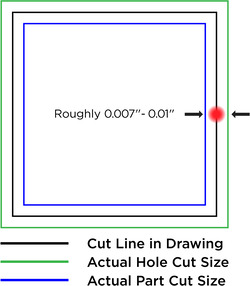

The kerf of our laser is roughly 0.007" – 0.01" which causes parts to be slightly smaller and have larger holes than how they are drawn. |

|---|

|

An example of melting along sharp angles for various thicknesses of acrylic (1.5 mm to 12 mm). |

|---|

While the possibilities of things that you can create using our laser cutting service may seem endless, there are still some limitations that you should keep in mind when considering our laser-cutting service:

- We can only cut two-dimensionally – no 3D designs, or beveled edges.

- All laser-cut dimensions will vary slightly due to the laser’s kerf (beam width). While we typically expect a kerf width of ~0.007″ – 0.010″, we do not guarantee any particular tolerance as there are many factors that affect the exact kerf size (material type, material thickness, material flatness, size and shape of your part and overall layout, and more).

- Having cut lines too close together can sometimes cause the material between the cuts to break, melt, warp, or become brittle due to the heat from the laser. This includes parts with sharp angles that narrow into a sharp tip. We generally recommend having no areas that are narrower than the thickness of the material you are using.

- The laser’s beam is cone-shaped which causes the parts to have a slight (1-2 degree) taper. The kerf width is smaller on the front than it is on the back of the material.

- The laser’s beam is not perfectly circular, which means squares will not be perfectly square, and circles are not perfectly circular (for parts that need to be perfectly circular, we suggest cutting smaller holes and cleaning them up with a drill).

- Most sheet material thicknesses can vary slightly, and different materials have different thickness tolerances. We cannot promise anything beyond what the material manufacturers do, nor do we offer material pre-screening.

- Laser-cut steel is not guaranteed to be free of dross and burring, and we do not offer any post-cutting services such as deburring, tumbling, polishing, bending, welding, anodizing, or coating.

- Some materials, like acrylic, come with a protective film or paper masking layer applied to the surface, while other materials (e.g., ABS, Delrin, styrene, MDF, plywood, etc.) do not. We typically cut and ship the materials as they are when we receive them, but can add masking upon request (we charge more to mask materials).

- Parts cut from paper-masked parts will ship with the masking still on (we have a video that shows an easy way to unmask acrylic).

- Parts cut from materials without masking may have burn markings from the cutting process.

- Some materials will have noticeable discoloration or char on the edges from the laser, such as wood, paper, rubbers, and fabrics. For more material-specific info, please see our materials page.

- The material sits on a metal grid during cutting. When the laser cuts through the material, it hits the grid and bounces back and hits the bottom of the material, causing a small dent or mark. The backs of the parts will usually have small dents along the cut edges of the part wherever the laser, grid, and material meet.

5. File setup instructions

We use CorelDRAW to prepare your previews and laser-cut parts, which can handle a variety of vector and two-dimensional CAD drawings:

| File types we can use | File types we cannot use |

|---|---|

| ✓ CDR (CorelDRAW) | ✘ SLDDRW (SolidWorks) |

| ✓ AI (Adobe Illustrator) | ✘ SLDPRT (SolidWorks) |

| ✓ EPS (Adobe Illustrator) | ✘ SLDASM (SolidWorks) |

| ✓ DXF (must be 2D) | ✘ PSD (Adobe Photoshop) |

| ✓ DWG (must be 2D) | ✘ STEP |

| ✓ PDF (cut objects must be vector-based) | ✘ STL |

| Bitmap images (JPG, PNG, TIF, etc.) can be used for engraving only (not for cutting) | ✘ STP |

| SVG files are acceptable but often have scaling issues, sending an EPS or PDF is preferred | ✘ Any other 3D format file |

Laser cutting file set up instructions

Here are some basic instructions for preparing your file for a quote. Additional tutorials and tips can also be found on our blog.

- Use thin lines with a stroke width set to “0”, “hairline”, or <0.003″.

- Use different colors or layers to separate cut lines, score lines, and engravings. We prefer:

- RGB Blue lines less than 0.003″ wide for cutting.

- RGB Red lines less than 0.003″ wide for scoring.

- RGB Black color-fill, or lines greater than 0.003″ wide for engraving (note: all engravings are surface-etched unless you specifically request for a deeper engraving).

- Green for notes and reference objects that you do not want us to cut (e.g., part or material size references, special instructions, etc.).

- Include a size reference with a label, such as a 1″ square, so it’s easy for us to verify the size of your layout and quote it accordingly.

- Convert all text to non-text objects to ensure that your design is preserved. Most programs use different terms for this operation, such as “explode text”, “convert to curves/paths/objects/outline”.

- Avoid narrow features that are thinner than the material you plan on using as this can result in your parts breaking, warping, melting, or becoming very brittle.

- Combine parts that use the same material into a single file, and avoid sending multiple files whenever possible.

- Use layout sizes that work well with the material size whenever possible, while reserving a 1/4″ margin:

- Standard plastic layout sizes:

- 11.5″ x 11.5″

- 11.5″ x 23.5″

- 23.5″ x 23.5″

- 23.5″ x 35.5″

- 23.5″ x 47.5″

- Standard plywood layout sizes:

- 11.5″ x 23.5″

- 23.5″ x 29.5″

- 29.5″ x 47.5″

- Note: We can handle larger layouts – up to 47.5″ x 47.5″ – but don’t usually stock sheets this large and prefer working with smaller, more manageable, layouts whenever possible.

- Standard plastic layout sizes:

Advanced file-setup tips

Adjust for the kerf width

You may want to adjust your cut paths to account for the approximate kerf width (the thickness of the beam), which is typically ~0.007″ – 0.010″, but varies based on many factors (see our capabilities and limitations page for more information). You can manually draw parts to be 0.007″ – 0.010″ wider (for exterior cuts) or smaller (for interior cuts), or use an automated line-offset or contour tool to do this for you.

Share lines to reduce cutting time for non-metal layouts

For most materials, you can nest parts right next to each other to reduce the cutting time and cost, but remember that you must delete one of the duplicate lines for this to be effective. Even though you might not be able to see them in the file, if you leave two lines stacked on top of each other, the laser cutter will recognize and cut both lines which can worsen the cut quality. We can accept line-shared layouts for most plastics, woods, foams, and rubbers, but we cannot use them for metals.

Round corners for stronger parts

If your parts include sharp corners, you might consider rounding them so they are less likely to crack upon impact – even adding a 1/16″ radius to a 90° angle can make a big difference!

Programs for drawing laser-cut parts

- CorelDRAW (Corel.com) is what we use and love. It is available as a one-time purchase and as yearly and monthly subscriptions, and a free-trial period.

- Adobe Illustrator (Adobe.com) is the most popular vector graphics editor available, making it easy to find online guides and tutorials. Monthly and yearly subscriptions are available, as well as a free trial.

- Inkscape (Inkscape.org) is a free, open-source, vector graphics editor. While it works great for designing laser-cut parts, Inkscape’s default file format (SVG) often has scaling issues when opened with other programs. Please save your files as a PDF or EPS instead of an SVG when submitting your file for a quote.

- LibreCAD (LibreCAD.org) is a free, open-source, CAD software capable of creating two-dimensional CAD files for laser-cutting.

6. Materials

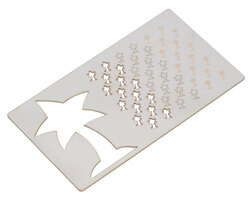

|

Through-cutting, vector etching, and raster engraving on stainless steel. |

|---|

|

Through-cutting, vector etching, and raster engraving on mild steel. |

|---|

|

Through-cutting, vector etching, and raster engraving on spring steel. |

|---|

We can laser cut plastics, woods, metals, rubbers, foams, and papers. We can handle some materials up to 1" thick, but the maximum thickness varies depending on the material. We stock some materials including acrylic, birch plywood, MDF, mild and stainless steel, aluminum, ABS, Delrin, and more. For a complete list of the materials we stock, and available thicknesses and colors, see our quote request form. You are also welcome to supply your own material for us to cut.

Materials we can laser cut

Here is a list of the materials that we can cut. If you do not see your material listed, we would be happy to try cutting it as long as it does not contain vinyl. To test a new material, please submit a quote request and provide details about your material in the special instructions section of the quote request form.

| Type | Material | Max Thickness | Notes |

|---|---|---|---|

| Plastics | ABS | 1/4″ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. It is machine-friendly and will not break or crack easily if dropped or hit. It has a hair-cell textured front surface, which hides fingerprints and scuffs well. The backside of the material is smooth and glossy, and since ABS does not come with masking, this surface is prone to scratches and markings. |

| Acrylic | 1″ | Also known as Plexiglas, Lucite, PMMA. Our favorite material to work with – cuts cleanly with a laser-polished edge. For more in-depth information on acrylic, please see Section 6.a | |

| Delrin | 1/4″ | Has smooth, glossy surfaces that often have scratches on them. Delrin is a very tough, slippery material that resists warping and deforming well and is commonly used to make gears. Its slick surface makes it difficult to adhere to without sanding. It is the most expensive plastic that we carry. | |

| HDPE | 1/16″ | Edges melt badly and produce a lot of dust that sticks to the parts when cut. | |

| Kapton | 0.050″ | Chars badly when cut, cutting adhesive-backed sheets increases the charring, and also causes the parts to be sticky. | |

| Mylar | 0.010″ | Also known as Polyester film. | |

| Nylon | 1/16″ | Edges melt, smell, and discolor badly when cut. | |

| PETG | 1/8″ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. PETG is not brittle, so parts do not crack or break easily. PETG comes with a film masking on both sides to protect the surface during the cutting process, but the edges still tend to melt and turn yellow from the laser cutting. | |

| Polyethylene | 1/8″ | Melts badly when cut. | |

| Polypropylene | 1/8″ | Melts somewhat when cut | |

| Styrene | 1/8″ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. Edges melt somewhat. | |

| Teflon | 1/8″ | Melts somewhat. | |

| Metals | Aluminum | 1/4″ | All metal parts are shipped without any post processing (e.g., deburring, tumbling, polishing, coating, etc.), and are not guaranteed to be free of blemishes or light scratches. Edges can have slight discoloration, and backs of parts might have burring (minimal burring for metals under 1/8″ thick, but more severe for thicker materials). |

| Brass | 1/8″ | ||

| Steel | 1/4″ | ||

| Stainless Steel | 1/4″ | ||

| Spring Steel | 1/4″ | ||

| Foams | Depron | 1″ | Was once a popular material for RC planes, but is now difficult to source in the U.S. |

| EPDM | 1″ | Edges will be have light char/soot on them. | |

| Neoprene | 1″ | Edges will be have light char/soot on them. | |

| Nylon | 1″ | Edges will be have light char/soot on them. | |

| Polyethylene | 1″ | Edges will be have light char/soot on them. | |

| Polyurethane | 1″ | Edges will be have light char/soot on them. | |

| Silicone | 1/8″ | Edges will be have light char/soot on them. | |

| Woods | Birch Ply | 1″ | A popular, eco-friendly plywood that is great for laser cutting. It is typically cut without masking, but can be masked to minimize burn markings for an additional fee. |

| MDF | 1″ | Lowest-cost material to laser cut. Does not come with protective masking, so surfaces will have some discolorations and burn markings from cutting. | |

| Rubbers | Buna-N | 3/32″ | Cuts okay, but parts will have a lot of char/soot on them from the cutting process (we ship the parts “as-cut” without dusting/cleaning them). |

| Neoprene | 3/32″ | ||

| Polyethylene | 1/8″ | ||

| Silicone | 1/8″ | ||

| Viton | 1/8″ | ||

| Others | Cardboard | Has a slight smell to it when laser cut. | |

| Cardstock / Paper | Can be laser cut, but is usually more cost-effective to plot/die cut it instead. Edges might show light burn marks, depending on the material color (dark colors hide the markings better). | ||

| Fabrics | We’ve cut various types of fabrics including acrylic, canvas, cordura, cotton, nylon, polyester, and wool, and have not had any trouble. Edges become cauterized (which helps prevent the fabric from fraying), but might have slight discoloration depending on the color. | ||

| Leather | 1/8″ | All leather (both natural and synthetic) smells very bad when laser cut, so you might have to air the parts out once you receive them. Synthetic leather MUST be vinyl-free. Edges will have noticeable char/soot on them. | |

| Magnetic sheet | 1/16″ | Edges char slightly when laser cut. |

Materials we cannot laser cut

We do not or cannot cut the following materials:

| Material | Notes |

|---|---|

| ✘ Carbon Fiber | |

| ✘ Copper | For copper parts, or other metals that are not listed above, please consider our friends at OSH Cut. |

| ✘ Polycarbonate | Difficult to laser cut, and burns very badly. |

| ✘ Vinyl | (And any other materials that include vinyl.) Releases toxic fumes. |

| ✘ PVC | Also commonly known as Cintra – contains vinyl, which releases toxic fumes. |

| ✘ PCB | We cannot cut printed circuit boards (FR4 and other materials). |

| ✘ Glass |

How to supply your own material for laser cutting

If you plan to supply material the material for your order, please mention this in the special instructions section in our quote request form and be sure to include the sheet size. When sending material:

- please wait until after you have received your quote before you ship it (in case we cannot cut that material, or your design, etc.).

- make sure to include your name and quote number with the shipment.

- make sure the material is flat, as warped or bowed materials can cause problems during cutting. Some materials, like rubbers and fabrics, can be shipped rolled since they will still lay flat right away, while others can take a very long time to flatten out.

- do not ship material that is longer than 48″ unless it can be cut down using scissors or you have made special arrangements with us for larger pieces.

- you can have suppliers ship directly to us to avoid having to pay an extra shipping charge.

- you are responsible for supplying any extra material needed to recut parts that do not come out well (we cover this when using our stock material).

- let us know what you would like us to do with the leftover material. We can hold it for another order in the near future, discard it, or send it to you along with your order (an additional shipping charge might be required).

Suppliers for laser-cutting materials

Here is a list of the acrylic suppliers that we use, and our customers use, frequently:

- McMaster-Carr — Highly-recommended for expedited laser-cutting orders – they ship fast!

- Delvie’s Plastics

- Johnson Plastics Plus — Large selection of two-tone “engravable” acrylics.

- TAP Plastics

- Inventables

- ePlastics

- Professional Plastics

- eStreet Plastics

- United States Plastics

6.a. More information about acrylic

Acrylic – also known by a variety of other names, including plexiglass, Plexi, perspex, lucite, and PMMA – is the most popular laser-cutting material that we carry as it is inexpensive and has an attractive finish with laser-polished edges that is ready for immediate display.

Acrylic is available in a variety of thicknesses (which we can cut up to 1″), and a variety of transparent, translucent, and opaque colors, including fluorescent and mirrored options too. We have a large selection of acrylic colors and thickness available; for a complete list of our stocked materials, please see our quote request page. If you need something else, we might be able to special-order it for you from our suppliers, or you can ship it to us instead.

While acrylic is lighter and stronger than glass, it is also somewhat brittle and is susceptible to cracking if it is dropped or hit – especially at sharp corners in your design – or if drilled using the wrong bit or poor technique. We do not recommend acrylic for applications that require rough handling.

You can glue acrylic together using special acrylic glues such as Weld-On. Please contact your local hardware store and ask for glues used for acrylic.

How to care for and clean acrylic parts

Acrylic comes with a protective, paper or film, masking attached to the surface, which we leave on when we cut and ship your parts to avoid scratching the surface. Once you receive the parts, you will need to peel the masking. Here is a video that shows an easy way to unmask acrylic, which is especially helpful if you have a lot of parts!

After you have unmasked the acrylic, it can naturally build up a static charge, which can attract dirt and dust.

To clean acrylic, we always recommend that you use a very soft microfiber cloth, and avoid using paper towels, as their rough surfaces can often cause more scratches on the acrylic surface. Usually, a simple mixture of warm water and mild dish soap will do the trick, and you should avoid using harsh household cleaning products like Windex. For a more thorough cleaning, we recommend Novus #1 plastic cleaner, which is available in multiple kit sizes, or separately, from a variety of retailers, including Amazon.

WARNING: Never use isopropyl (rubbing) alcohol to clean acrylic as it will cause the acrylic to crack!

Cast and extruded acrylic

Acrylic starts as a liquid resin, which is either cast into a glass mold, or continuously extruded through a machine to make flat sheets. Both methods have advantages and disadvantages against each other, and the following table highlights some of the most important differences:

| Cast Acrylic | Extruded Acrylic |

|---|---|

| Turns frosty white when engraved, which provides high-contrast engravings | Engraving is difficult to see from most angles |

| Thickness varies much more | Better thickness tolerances |

| Higher molecular weight; less susceptible to cracking, e.g. when machined | Lower molecular weight; more susceptible to cracking, e.g. when machined |

| Higher melting point results in less polished finish | Lower melting point provides a more polished finish |

| Wider variety of colors available | Fewer color options |

Common uses for laser-cut acrylic

Acrylic is commonly used in place of glass for a variety of different uses, such as:

|

|

|

Pictures of some acrylic colors we stock

Below are pictures of most of the 3mm acrylic colors we stock. Your monitor will probably not show the colors exactly, but the pictures should give you some idea of what the colors are like. We do stock other colors and materials: see the quote request form for a complete list.