Support » Custom Laser Cutting Guide »

6. Materials

|

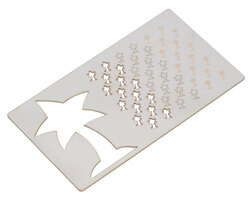

Through-cutting, vector etching, and raster engraving on stainless steel. |

|---|

|

Through-cutting, vector etching, and raster engraving on mild steel. |

|---|

|

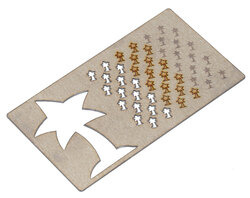

Through-cutting, vector etching, and raster engraving on spring steel. |

|---|

We can laser cut plastics, woods, metals, rubbers, foams, and papers. We can handle some materials up to 1" thick, but the maximum thickness varies depending on the material. We stock some materials including acrylic, birch plywood, MDF, mild and stainless steel, aluminum, ABS, Delrin, and more. For a complete list of the materials we stock, and available thicknesses and colors, see our quote request form. You are also welcome to supply your own material for us to cut.

Materials we can laser cut

Here is a list of the materials that we can cut. If you do not see your material listed, we would be happy to try cutting it as long as it does not contain vinyl. To test a new material, please submit a quote request and provide details about your material in the special instructions section of the quote request form.

| Type | Material | Max Thickness | Notes |

|---|---|---|---|

| Plastics | ABS | 1/4″ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. It is machine-friendly and will not break or crack easily if dropped or hit. It has a hair-cell textured front surface, which hides fingerprints and scuffs well. The backside of the material is smooth and glossy, and since ABS does not come with masking, this surface is prone to scratches and markings. |

| Acrylic | 1″ | Also known as Plexiglas, Lucite, PMMA. Our favorite material to work with – cuts cleanly with a laser-polished edge. For more in-depth information on acrylic, please see Section 6.a | |

| Delrin | 1/4″ | Has smooth, glossy surfaces that often have scratches on them. Delrin is a very tough, slippery material that resists warping and deforming well and is commonly used to make gears. Its slick surface makes it difficult to adhere to without sanding. It is the most expensive plastic that we carry. | |

| HDPE | 1/16″ | Edges melt badly and produce a lot of dust that sticks to the parts when cut. | |

| Kapton | 0.050″ | Chars badly when cut, cutting adhesive-backed sheets increases the charring, and also causes the parts to be sticky. | |

| Mylar | 0.010″ | Also known as Polyester film. | |

| Nylon | 1/16″ | Edges melt, smell, and discolor badly when cut. | |

| PETG | 1/8″ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. PETG is not brittle, so parts do not crack or break easily. PETG comes with a film masking on both sides to protect the surface during the cutting process, but the edges still tend to melt and turn yellow from the laser cutting. | |

| Polyethylene | 1/8″ | Melts badly when cut. | |

| Polypropylene | 1/8″ | Melts somewhat when cut | |

| Styrene | 1/8″ | Smells very bad when cut, so you might have to wash or air out the parts out upon receiving them to get rid of the smell. Edges melt somewhat. | |

| Teflon | 1/8″ | Melts somewhat. | |

| Metals | Aluminum | 1/4″ | All metal parts are shipped without any post processing (e.g., deburring, tumbling, polishing, coating, etc.), and are not guaranteed to be free of blemishes or light scratches. Edges can have slight discoloration, and backs of parts might have burring (minimal burring for metals under 1/8″ thick, but more severe for thicker materials). |

| Brass | 1/8″ | ||

| Steel | 1/4″ | ||

| Stainless Steel | 1/4″ | ||

| Spring Steel | 1/4″ | ||

| Foams | Depron | 1″ | Was once a popular material for RC planes, but is now difficult to source in the U.S. |

| EPDM | 1″ | Edges will be have light char/soot on them. | |

| Neoprene | 1″ | Edges will be have light char/soot on them. | |

| Nylon | 1″ | Edges will be have light char/soot on them. | |

| Polyethylene | 1″ | Edges will be have light char/soot on them. | |

| Polyurethane | 1″ | Edges will be have light char/soot on them. | |

| Silicone | 1/8″ | Edges will be have light char/soot on them. | |

| Woods | Birch Ply | 1″ | A popular, eco-friendly plywood that is great for laser cutting. It is typically cut without masking, but can be masked to minimize burn markings for an additional fee. |

| MDF | 1″ | Lowest-cost material to laser cut. Does not come with protective masking, so surfaces will have some discolorations and burn markings from cutting. | |

| Rubbers | Buna-N | 3/32″ | Cuts okay, but parts will have a lot of char/soot on them from the cutting process (we ship the parts “as-cut” without dusting/cleaning them). |

| Neoprene | 3/32″ | ||

| Polyethylene | 1/8″ | ||

| Silicone | 1/8″ | ||

| Viton | 1/8″ | ||

| Others | Cardboard | Has a slight smell to it when laser cut. | |

| Cardstock / Paper | Can be laser cut, but is usually more cost-effective to plot/die cut it instead. Edges might show light burn marks, depending on the material color (dark colors hide the markings better). | ||

| Fabrics | We’ve cut various types of fabrics including acrylic, canvas, cordura, cotton, nylon, polyester, and wool, and have not had any trouble. Edges become cauterized (which helps prevent the fabric from fraying), but might have slight discoloration depending on the color. | ||

| Leather | 1/8″ | All leather (both natural and synthetic) smells very bad when laser cut, so you might have to air the parts out once you receive them. Synthetic leather MUST be vinyl-free. Edges will have noticeable char/soot on them. | |

| Magnetic sheet | 1/16″ | Edges char slightly when laser cut. |

Materials we cannot laser cut

We do not or cannot cut the following materials:

| Material | Notes |

|---|---|

| ✘ Carbon Fiber | |

| ✘ Copper | For copper parts, or other metals that are not listed above, please consider our friends at OSH Cut. |

| ✘ Polycarbonate | Difficult to laser cut, and burns very badly. |

| ✘ Vinyl | (And any other materials that include vinyl.) Releases toxic fumes. |

| ✘ PVC | Also commonly known as Cintra – contains vinyl, which releases toxic fumes. |

| ✘ PCB | We cannot cut printed circuit boards (FR4 and other materials). |

| ✘ Glass |

How to supply your own material for laser cutting

If you plan to supply material the material for your order, please mention this in the special instructions section in our quote request form and be sure to include the sheet size. When sending material:

- please wait until after you have received your quote before you ship it (in case we cannot cut that material, or your design, etc.).

- make sure to include your name and quote number with the shipment.

- make sure the material is flat, as warped or bowed materials can cause problems during cutting. Some materials, like rubbers and fabrics, can be shipped rolled since they will still lay flat right away, while others can take a very long time to flatten out.

- do not ship material that is longer than 48″ unless it can be cut down using scissors or you have made special arrangements with us for larger pieces.

- you can have suppliers ship directly to us to avoid having to pay an extra shipping charge.

- you are responsible for supplying any extra material needed to recut parts that do not come out well (we cover this when using our stock material).

- let us know what you would like us to do with the leftover material. We can hold it for another order in the near future, discard it, or send it to you along with your order (an additional shipping charge might be required).

Suppliers for laser-cutting materials

Here is a list of the acrylic suppliers that we use, and our customers use, frequently:

- McMaster-Carr — Highly-recommended for expedited laser-cutting orders – they ship fast!

- Delvie’s Plastics

- Johnson Plastics Plus — Large selection of two-tone “engravable” acrylics.

- TAP Plastics

- Inventables

- ePlastics

- Professional Plastics

- eStreet Plastics

- United States Plastics